Industrial Design

Tyrell 3 Transport Information System

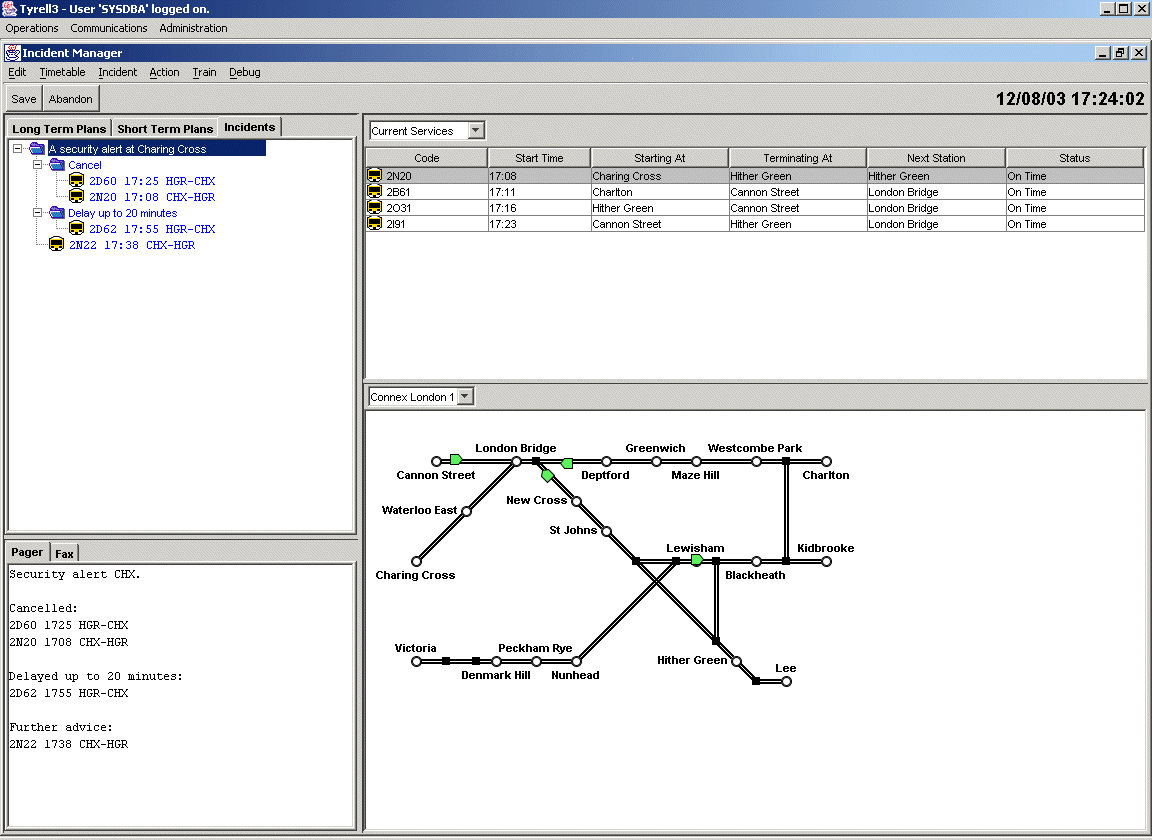

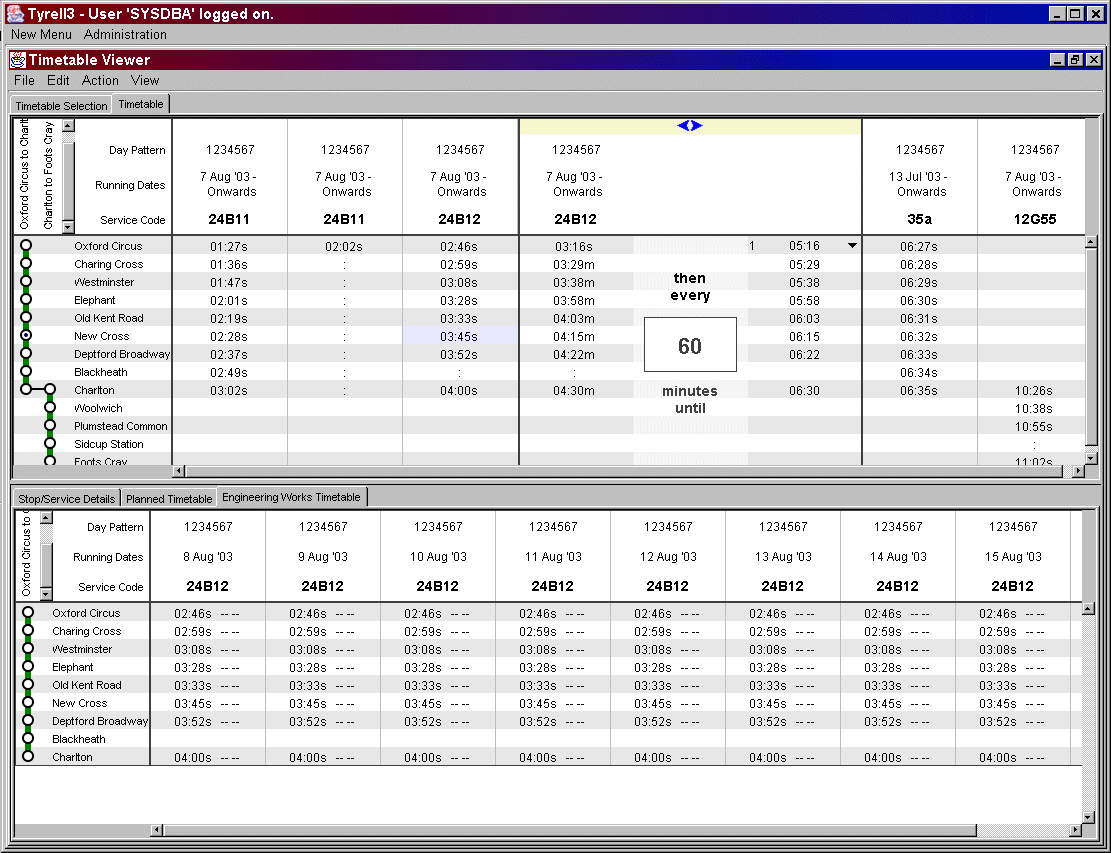

In March 2001 we began a new project named Tyrell 3 which was

intended to cater for a much broader information need and centred

around a database which catered for basic timetabling as well short

term alterations and incidents. It would provide this information in

many different forms to suit the subscriber enquiring. This work

included some complex database design of which I did a great deal

with general participation from three others.

In March 2001 we began a new project named Tyrell 3 which was

intended to cater for a much broader information need and centred

around a database which catered for basic timetabling as well short

term alterations and incidents. It would provide this information in

many different forms to suit the subscriber enquiring. This work

included some complex database design of which I did a great deal

with general participation from three others.

I managed the Tyrell3 system development project until I appointed

one of the team to take over around September 2003 but

I continued to directed the Tyrell3 system development project with extensive involvement in the transport database design.

LCD 1

LCD1 Outdoor Display

I designed and subcontracted manufacture of sheet metal and machined components for these displays. Designs were done using SolidWorks 3d CAD software. I also wrote the software for use on the displays themselves.

LCD1 is a rugged outdoor LCD based display designed to operate from -20C to +40C. LCD1 was intended to fit in with the modern steel architecture. See picture. My duties were;

What I did for this product;

- Software (in C) - Yes

- Electronics - No

- Mechanical Design - Yes

- Asthetic Design - Yes

- Thermal Flow - Yes

- Radio Emissions - Yes

LCD 1

LCD1 Outdoor Display

It had been clear to me for a couple of years that the days of bulky displays like the IDU (TV style outdoor display) were numbered and that flat screen technology was required. In response to an expression of interest I personally designed our first flat screen based display known as LCD1 in March 2002 using "Solid Works" a leading professional CAD package.

I sorted out the thermal management issues of putting an LCD display outdoors, the aesthetics of fitting in to the more desirable modern public architecture, and the strength issues since such a unit clearly is a target for vandalism. I also wrote the software for the display but one of my employees produced the electronics on the internal PCBs. Operating temperature from -20C to +40C.

Zeus Rugged Computer

What I did for this product;

- Electronics - Yes

- Mechanical Design - Yes

- Asthetic Design - Yes

- Thermal Flow - Yes

- Radio Emissions - Yes

I designed a rugged PC known as "Zeus" which achieved, as intended, a very low levels of radio emission due to its special ground plane and careful connector layout. Also all connectors were of locking types so as to make the system immune to vibration.

This was for possible use on trains where vibration would be a significant factor. Initially I looked at military plugs and sockets but found them to be lacking when it came to safety.

Travel Terminal

In January 1994 I began the third generation of the Travel Terminal

software in 'C' It took about two to three years of work. I also

provided field support for it in the early years. This software

evolved from the second generation to become very close to bug free.

I think sold over 150 units.

The Travel Terminal software allows information about travel incidents to be entered on forms displayed on the screen. Once the information is entered it is distributed automatically to a selection of contacts who may be using Travel Terminals, Mercury Pagers, Faxes, IDUs or other computer systems, on which to receive the information. At its peak this system was used by ALL but 2 of the rail control rooms in the UK and also at 30 of the 60 police control rooms across the country in addition to other sites.

What I did for this product;

- Software (in C) - Yes

- Database Design - Yes

IDU

IDU (TV style outdoor display)

What I did for this product;

- Software (in C) - Yes

- Electronics - Yes

- Mechanical Design - Some

- Asthetic Design - No

- Thermal Flow - Some

- Radio Emissions - Some

The Intelligent Display Unit was basically a CRT screen driven by a computer and contained in a fibreglass housing with thermal control. Developed originally for a demo this beast became real and went on to appear on over 50 stations. For cold testing for three months at -15C in 1995, I used a spare fridge belonging to the local butcher.

Tyrell 1 and 2

In August 97 I began managing one programmer to write some new PC based Travel Terminal software to be written in C++ and known as Tyrell. It went into a control rooms about June 99 at this point there were three programmers. This product has continued to develop and is now used for the management, distribution and presentation of public transport information by twenty-one train-operating companies, city and county councils, Transport for London, Railtrack, several police forces and the major travel information media organisations. Sold over 110 units.

What I did for these products;

- Software (in C) - Yes

- Database Design - Some

Mechanical Engineering

Despite no initial background in mechanical engineering I was drawn into it as it became necessary to commission special components, initially just a few plates, to build the displays. The first display produced by NAL the IDU was simply the combination of a standard watertight housing containing a CRT, a computer in a custom built metal housing and some custom mounting plates.

Industrial Design

I did any industrial design we needed until in November 2003 I employed a product designer to take on future product design work.

Radio Work

I did or managed all the radio work for the pre-tests for CE radio emissions. We passed the tests first time on all equipment.

I was responsible for the radio communications between displays and the software involved.

Electronic Design

I managed and directed electronic design work for our display's environmental control systems.

Despite my interest in electronics I have not done any significant electronic circuit design work with NAL but I have supervised that design and checked circuit designs at component level. I was also involved in fault finding and on site repair and installation of displays.

Production Control

I was responsible for efficient assembly setup. I developed and implemented the process for controlling component stock levels for builds and spares so as to avoid stock taking between building each batch of displays. I worked on and managed builds of up to twenty displays at a time optimising the working methods. I developed a "job kits system" which broke the work down into simple jobs that could be done reliably with casual labour and also made stock control very easy.

I worked on and managed builds of up to twenty displays optimising the time spend on the jobs. I managed and participated in mechanical engineering until March 2001 after which I continued to direct some of the work.

Maintenance Control

I established a parts tracking system for our field equipment so that we could keep a history of the pagers and computers etc. that were often taken from one system repaired and then used in another.

Quality

On installing a reasonable number of IDUs we found ourselves getting an unexpectedly high fault rate. Plotting the fault rate showed a peek and I noted that this corresponded to a time when we had had heavy rain. We look for any signs of water ingress. I established the cause of the leak as badly cured fibreglass that had warped causing water to rest against a rubber seal. I suggested a fix which the supplier then manufactured but this experience, was sufficient for me to design an entire new unit from stainless steel. The LCD1.